Our Nest’packer devices are mechanical units fitted in the collating unit, between the original product selection system and the lapping unit.

They are an easy, reliable and economical solution to adapt shrink-wrappers to nested packs :

- while retaining the possibility to produce «conventional» packs,

- without modifying the product selection system,

- without having to extend the machinery,

- without any modification on electrical wiring and controllers,

- retaining your current conveying system and your palletizer,

- choosing between our 4 patterns the one that offers you the higher savings.

They can be fitted on all shrink-wrappers makes and models (Sidel, Cermerx, Krones, KHS-Kisters, ZVT, Ocme, SMI, Dimac...) : one single solution for all your installed machinery, it’s easier !

One day is enough to adapt your production line (device set up + process validation).

- Our Nest’packer devices function with :

- PET bottles with flat base

- PET bottles with petaloid base

- HDPE bottles

- cans

- glass bottles

- tins

for containers ranging from 25cl up to 2l

for groupings from 6 to 40 containers

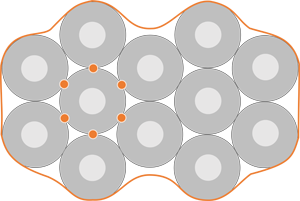

for symmetrical and asymmetrical staggering, staggering of rows and semi-staggering.

Over 70 lines already fitted with our solutions !

Nest’Packer asymmetrical staggering device :

Femaag has invented and patented a solution that allows to produce very easily assymetrical nested packs on continuous motion shrink-wrappers. Our Nest’packer device just has to be fitted in the collating unit. With this non-powered purely mechanical device, it is no longer necessary to entirely review the entry and selection areas of the machine : moving to nested packs is done in a twinckle.