To reduce the volume of your packs

If spheres and cylinders naturally arrange themselves in staggered rows, it is because nature abhors a vacuum.This arrangement is indeed the one that shows the less void between each element.

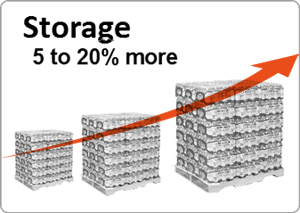

Grouping bottles, cans or glass jars in staggered rows thus allows to reduce the global volume of packs from 5 to 20%.

This is as much storage capacity gained for you and your distributors.

It also means less pallets to be handled and transported.

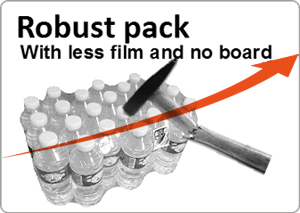

To save on packaging materials

The arrangement in staggered rows is the one that offers the maximum number of contact points between grouped products (6 against 4 for linear arrangement).

The additional friction exerted on containers increases the resistance of the pack.

Higher resistance allows savings on primary, secondary and tertiary packaging materials :

- bottle’s weight reduction,

- elimination of cardboard trays and glue,

- shrink-film’s thickness reduction,

- reduction of pallets’s covers thickness or stretch film’s length.

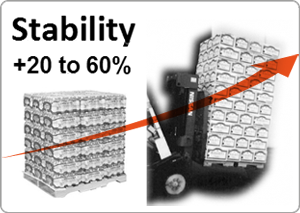

To avoid pallets to be torn up

Arrangement in staggered rows brings more stiffness to shrink-packs and allows them to fit better into each other. Resistance to horizontal shear is thus considerably enhanced and pallets are much more stable.

A comparative testing carried out on a pallet of conventional packs and a pallet of nested packs has shown that the latter one is able to withstand additional efforts of

+ 60% in lateral acceleration (curves, traffic circles) and + 25% in longitudinal acceleration (acceleration/braking), and this despite an added weight of 11% (pallet loading optimization).

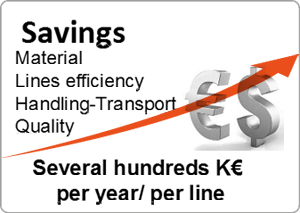

To reduce your production costs and your carbon footprint

Economical and eco-friendly, the nested pack takes it all !

With it, you will purchase and use less packaging materials, thus saving money and reducing your environmental impact.

For the same production level, you will use less pallets thus increasing your transportation and storage efficiency.

Femaag’s staggering devices also lead to an output increase of 10% through lines that are easier to run, generate less incidents and require less maintenance.

Moving to nested packs will allow you to maintain your profit margins while reducing your carbon footprint (320 tons CO2 equivalent saved each year on a model project).

Customer's testimony: Our customer SPA have been nominated for nested pack by the "Greener Packaging Award"

> See the video